Call: 08071630524

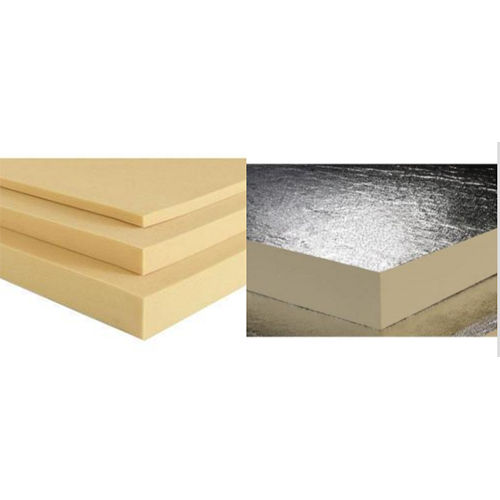

Rigid Polyurethane Foam Slabs

MOQ : 100 Square Foots

Rigid Polyurethane Foam Slabs Specification

- Thermal Conductivity

- 0.022 0.028 W/mK

- Density

- 40-42 kg/m

- Dimensional Stability

- Excellent

- Thickness

- As per requirement

- Color

- Yellowish

- Compressive Strength

- Min. 2.1 kg/cm

- Moisture Resistance

- High

- Length & Width

- Custom sizes available

- Adhesion Capability

- Good to most substrates

- Eco Friendly

- CFC and HCFC free

- Operating Temperature Range

- -180C to +110C

- Fire Resistance

- Self extinguishing (as per IS 12436:1988)

- Application

- Thermal insulation in refrigeration, roofing, and cold storage

- Water Absorption

- <1% by volume

- Material

- Rigid Polyurethane Foam

- Shape

- Slab

- Packaging

- Standard/bulk packaging as required

- Surface Finish

- Smooth

- Closed Cell Content

- >90%

Rigid Polyurethane Foam Slabs Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 5000 Square Foots Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Rigid Polyurethane Foam Slabs

- Thickness: 25-150 mm

- It has compressive strength.

- It is moisture resistant, fungi and bacteria resistant.

- Unfaced/Faced with FSK, Aluminium foil, Kraft paper.

- It is widely used in automobiles in bus seats, motor cycles, scooters, apart from the furnishing sector.

Advanced Fire Resistance and Safety

Our rigid polyurethane foam slabs comply with IS 12436:1988 standards for self-extinguishing properties, offering heightened safety in both industrial and commercial applications. Their closed cell structure further enhances fire resistance and maintains low water absorption, making them a secure choice for insulation.

Superior Thermal Insulation for Extreme Conditions

With an operating range from -180C up to +110C and low thermal conductivity, these slabs ensure stable performance even in challenging environments. Excellent dimensional stability and high compressive strength make them suitable for roofing, refrigeration units, and cold storage facilities.

Environmentally Conscious and Versatile Solutions

Produced without CFCs or HCFCs, our foam slabs prioritize eco-friendly insulation options without compromising quality. Offering custom sizes, thicknesses, and a smooth finish, they adapt seamlessly to varied project requirements, supported by good adhesion to most substrates.

FAQ's of Rigid Polyurethane Foam Slabs:

Q: How do the rigid polyurethane foam slabs provide fire resistance?

A: The slabs are self-extinguishing in nature, certified as per IS 12436:1988, which means they minimize the spread of flames and can extinguish themselves if exposed to fire, enhancing safety in insulated environments.Q: What operating temperature range can these foam slabs withstand?

A: Our foam slabs maintain performance across a wide temperature spectrum, suitable for conditions between -180C and +110C, making them viable for extreme cold and heat applications.Q: When should I choose custom sizes and thicknesses for my insulation project?

A: Custom sizing and thickness are recommended when you require tailored insulation to fit specific architectural spaces, ensuring optimum coverage and thermal efficiency for your unique project needs.Q: Where are these polyurethane foam slabs typically used?

A: They are widely applied in roofing systems, refrigeration units, and cold storage facilities where high thermal insulation and moisture resistance are critical to maintaining energy efficiency and protecting stored goods.Q: What is involved in the process of installing these foam slabs?

A: Installation entails measuring and cutting the slabs to desired dimensions, ensuring the smooth surface finish allows for good adhesion with most substrates, and then properly fixing them in place, either as panels or bulk depending on requirement.Q: How does the high closed cell content benefit insulation performance?

A: Having a closed cell content above 90% significantly reduces thermal conductivity and water absorption, providing superior insulation and maintaining long-term dimensional stability even in humid conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Insulation Services Category

Stainless Steel Sheet Coils and Bands

Price 200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese