Call: 08071630524

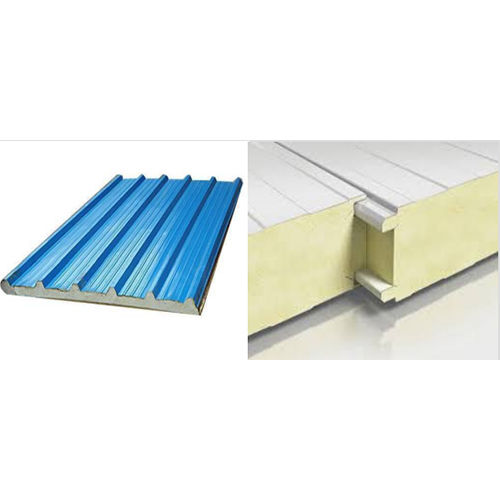

Rigid Polyurethane Foam Sandwich Panel

MOQ : 100 Square Foots

Rigid Polyurethane Foam Sandwich Panel Specification

- Color Options

- Multiple standard and custom colors

- Material

- Polyurethane (PU) Foam Core, Steel Sheet Faces

- Width

- standard 1 meter

- Edge Profile

- Tongue and groove joint

- Product Name

- Rigid Polyurethane Foam Sandwich Panel

- Installation

- Easy and quick installation, lightweight panels

- Surface

- Pre-painted / coated steel

- Temperature Range

- -40°C to +80°C

- Insulation Value

- High thermal insulation efficiency

- Sound Insulation

- Good acoustic performance

- Length

- custom as per requirement

- Moisture Resistance

- Excellent

- Panel Thickness

- varies (typically 30 mm to 200 mm)

- Application

- Cold storage, clean rooms, industrial buildings

- Finishing

- Smooth, embossed, or textured options

- Fire Resistance

- Self-extinguishing, fire retardant

- Compressive Strength

- > 150 kPa

Rigid Polyurethane Foam Sandwich Panel Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 5000 Square Foots Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Rigid Polyurethane Foam Sandwich Panel

- It is a double-layer color metal sheets with polyurethane rigid foam as an insulation layer.

- It has high heat insulation properties.

- All weather proof.

- Fire resistant and corrosion resistant.

- Long term stability.

- Usually used in the wall and roof enclosure system of industrial plants, warehouses, cold storages, integrated houses and prefabricated houses.

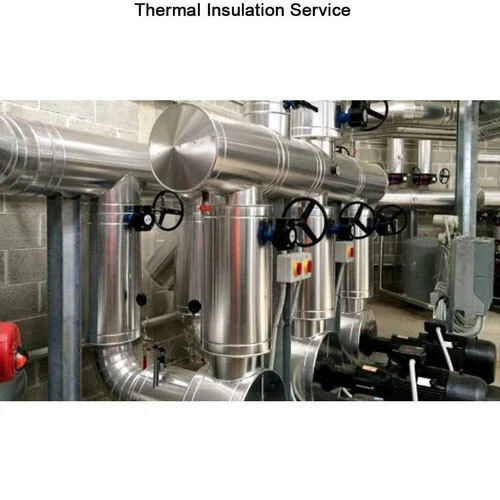

Superior Thermal Insulation for Demanding Applications

These sandwich panels deliver high thermal insulation efficiency, making them ideal for environments requiring controlled temperatures, such as cold storage or clean rooms. Their rigid polyurethane core and steel faces provide reliable performance, ensuring consistent energy savings and comfort.

Quick and Hassle-Free Installation

Designed with tongue and groove edge profiles, the lightweight panels enable rapid and secure installation. Whether used in industrial settings or commercial interiors, the process is straightforward, minimizing downtime and labor costs.

Versatile Finishing and Color Selections

Choose from smooth, embossed, or textured finishes, and a wide range of standard or custom colors. Panels can be tailored for both functional requirements and coordinated aesthetics, enhancing the design flexibility for builders and architects.

FAQ's of Rigid Polyurethane Foam Sandwich Panel:

Q: How is the Rigid Polyurethane Foam Sandwich Panel installed?

A: Installation is quick and easy, thanks to the tongue and groove joint system and lightweight design. Panels can be securely joined and fixed in place without extensive tools or heavy machinery, reducing overall project time.Q: What applications are suitable for these sandwich panels?

A: They are ideal for cold storage facilities, clean rooms, and various industrial building projects. Their high insulation efficiency and moisture resistance suit environments that demand strict thermal control and hygiene.Q: When should I consider using these panels for my project?

A: Choose these panels when you require high thermal performance, fast installation, fire-retardant properties, and flexible design options-especially in industrial or temperature-sensitive applications.Q: Where are these panels manufactured and supplied?

A: The panels are manufactured and supplied by providers, traders, and service companies across India, ensuring support for regional projects and prompt delivery of custom specifications.Q: What is the benefit of the polyurethane (PU) foam core in these panels?

A: The PU foam core provides excellent thermal insulation, good moisture resistance, and helps improve structural strength. It also contributes to the fire-retardant and self-extinguishing properties of the panels.Q: How do I select the right panel thickness for my needs?

A: Panel thickness ranges from 30 mm to 200 mm and should be chosen based on insulation requirements, application type, and project specifications. Suppliers can assist in recommending the optimal thickness for each scenario.Q: What finishing and color options are available for these panels?

A: You can choose between smooth, embossed, or textured surface finishes and select from multiple standard or custom color options, enabling you to match the panels to your aesthetic and functional requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese